Case Studies On External Wall Insulation

We have partnered with EWI Pro to provide a series of case studies that highlight projects using external wall insulation. These case studies will showcase the benefits and effectiveness of EWI systems in improving energy efficiency and enhancing building aesthetics. Through detailed analysis and real-world examples, we aim to demonstrate how EWI Pro’s innovative solutions have been successfully implemented across various properties, contributing to reduced energy consumption and increased property value. This collaboration will offer in-depth insights into the transformative impact of external wall insulation.

Case Study – Insulating Social Housing

Project Details

The Build-up

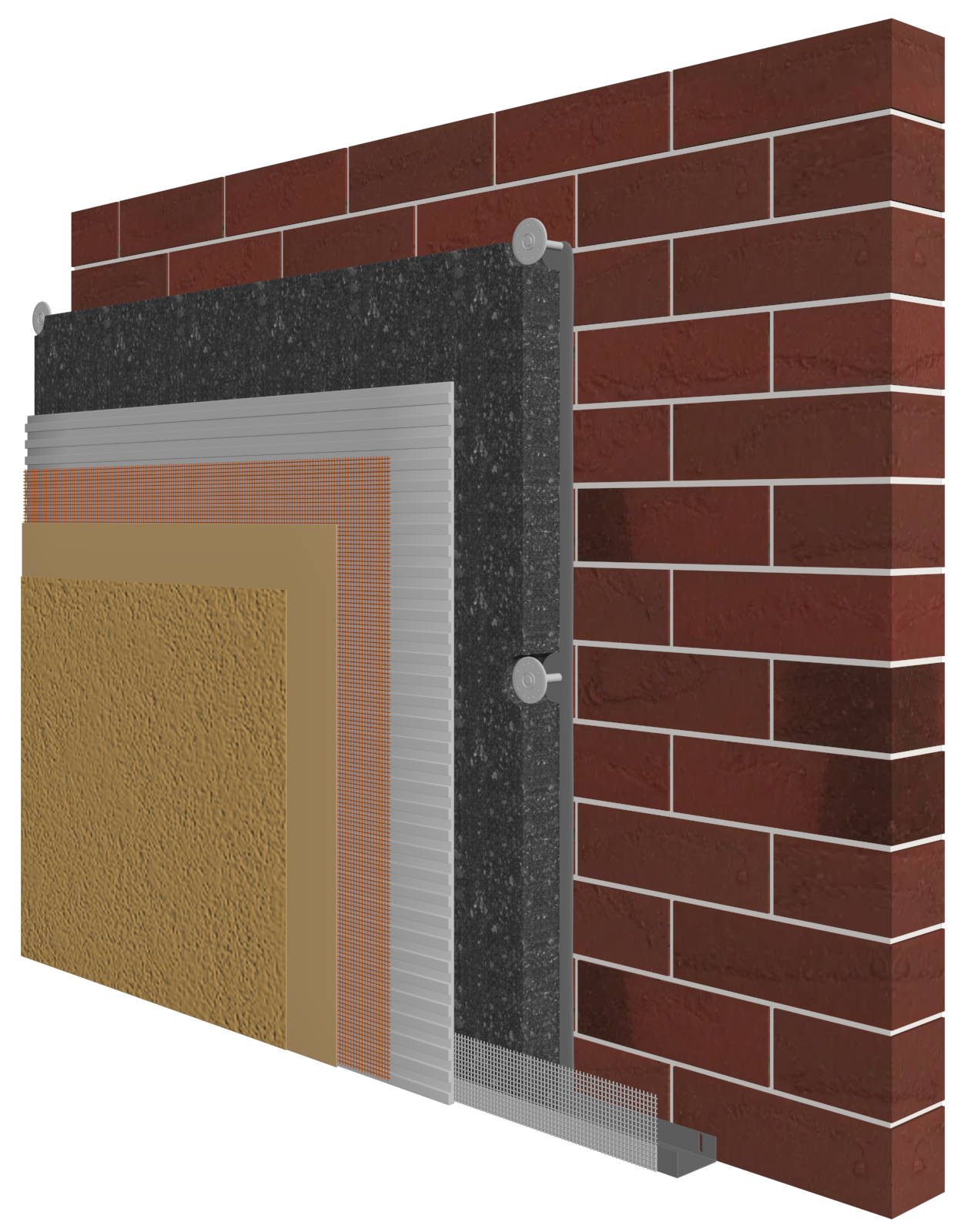

All 285 houses in this project utilise an EPS build-up, including our most popular basecoat and silicone render. Initially, the substrate needs to be thoroughly cleaned to ensure it’s dry and free from dust. Once prepared, it’s primed using EWI Pro’s Universal Primer. This primer is crucial as it significantly reduces the absorptive capacity of the substrate, thereby boosting the adhesion of the materials that will be applied in the subsequent steps.

Following substrate preparation, the insulation material, Expanded Polystyrene (EPS), is installed. The installation process benefits from the use of EWI Pro’s Premium Basecoat as an adhesive, which secures the EPS insulation to the substrate. This basecoat is exceptionally flexible and robust, therefore making it a reliable adhesive choice for this crucial step of the insulation installation.

Once the insulation is securely affixed, a basecoat layer is meticulously applied over the insulation boards. The Premium Basecoat is again utilised, this time to create a smooth surface on which the render will be applied. This basecoat serves as an ideal foundation for the subsequent steps, owing to its strength and flexibility.

The next step involves embedding the Orange Fibreglass Mesh within the basecoat. This mesh is fundamental as it significantly enhances the tensile strength and crack resistance of the system. It provides indispensable reinforcement, especially around vulnerable areas like windows and doors, ensuring the system is robust and durable.

Render primer is carefully applied to the reinforcement layer. This primer ensures that the render will adhere robustly to the basecoat, setting the stage for the final decorative finish. EWI Pro’s Silicone Render is a highly breathable and flexible material, making it an ideal choice for external wall insulation systems. It not only embellishes the external appearance of the property but also provides a long-lasting, crack-proof finish.

Following substrate preparation, the insulation material, Expanded Polystyrene (EPS), is installed. The installation process benefits from the use of EWI Pro’s Premium Basecoat as an adhesive, which secures the EPS insulation to the substrate. This basecoat is exceptionally flexible and robust, therefore making it a reliable adhesive choice for this crucial step of the insulation installation.

Once the insulation is securely affixed, a basecoat layer is meticulously applied over the insulation boards. The Premium Basecoat is again utilised, this time to create a smooth surface on which the render will be applied. This basecoat serves as an ideal foundation for the subsequent steps, owing to its strength and flexibility.

The next step involves embedding the Orange Fibreglass Mesh within the basecoat. This mesh is fundamental as it significantly enhances the tensile strength and crack resistance of the system. It provides indispensable reinforcement, especially around vulnerable areas like windows and doors, ensuring the system is robust and durable.

Render primer is carefully applied to the reinforcement layer. This primer ensures that the render will adhere robustly to the basecoat, setting the stage for the final decorative finish. EWI Pro’s Silicone Render is a highly breathable and flexible material, making it an ideal choice for external wall insulation systems. It not only embellishes the external appearance of the property but also provides a long-lasting, crack-proof finish.

Case Study – Mineral Wool onto Block

Project Details

The Build-up

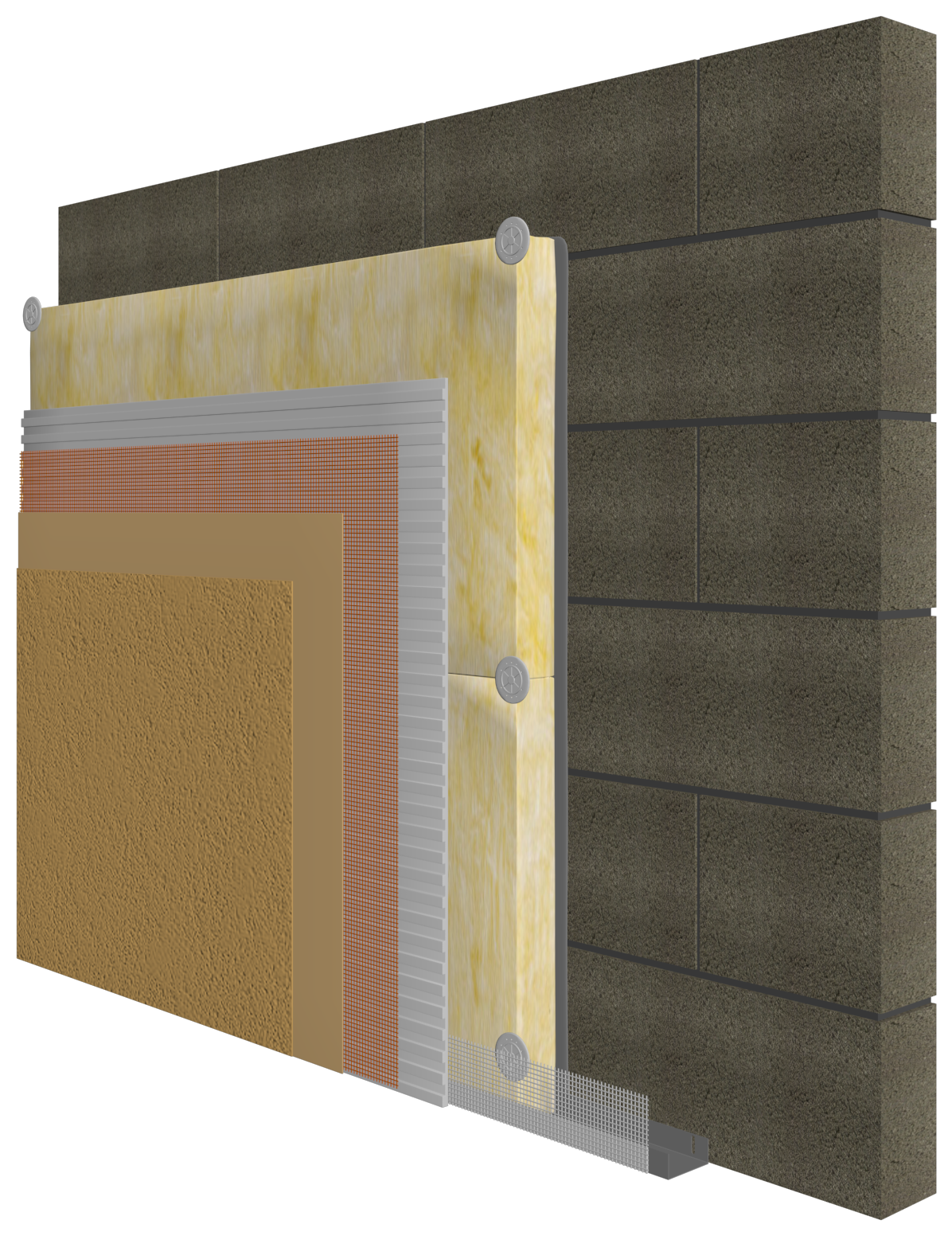

The use of Mineral Wool offers a multitude of benefits in addition to excellent thermal performance. With a thermal conductivity of 0.036W/m²K, Mineral Wool at 120mm achieves a U-value lower than the required industry standard. Other advantages include acoustic insulation and an A1 fire rating. The dual-density batts provide acoustic insulation; the outer layer is compressed during manufacturing, resulting in dimensionally stable boards.

Mineral Wool is ideal for use with a breathable thin-coat render system due to its vapour permeability. In this case study, the installer, who is also the homeowner, paired the insulation boards with EWI-076 Premium Bio Silicone Render on the recommendation of the EWI Pro Business Development Team. Eugene worked closely with the team and attended the Training Academy, with the final property façade showcasing his dedication and the team’s teachings.

The Premium Bio Silicone Render provides a freeze-proof and hydrophobic envelope for the property. Given the property’s positioning on the riverbank, EWI-076 is particularly beneficial as it offers active protection against biological growth, with slow-releasing antifungal agents maintaining the façade’s fresh appearance.

Mineral Wool is ideal for use with a breathable thin-coat render system due to its vapour permeability. In this case study, the installer, who is also the homeowner, paired the insulation boards with EWI-076 Premium Bio Silicone Render on the recommendation of the EWI Pro Business Development Team. Eugene worked closely with the team and attended the Training Academy, with the final property façade showcasing his dedication and the team’s teachings.

The Premium Bio Silicone Render provides a freeze-proof and hydrophobic envelope for the property. Given the property’s positioning on the riverbank, EWI-076 is particularly beneficial as it offers active protection against biological growth, with slow-releasing antifungal agents maintaining the façade’s fresh appearance.

Case Study – Domestic Kingspan K5

Project Details

The Build-up

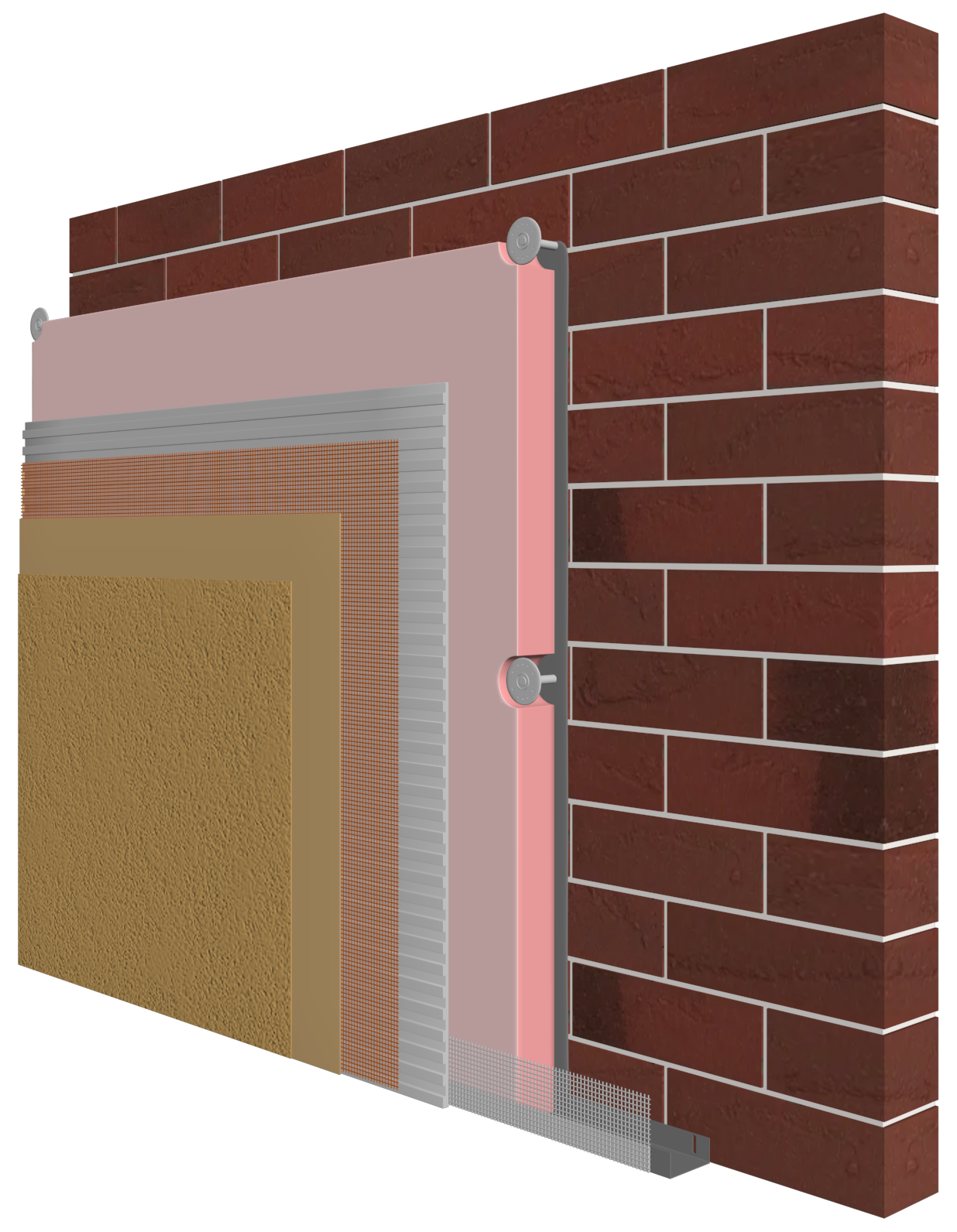

EWI Pro systems are specifically designed External Thermal Insulation Composite Systems (ETICS) renowned for their durability, flexibility, and excellent thermal performance. Each material in these systems is crafted to enhance a home’s façade and ensure compatibility, forming a continuous thermal envelope. This uninterrupted envelope is crucial in preventing cold bridges, which can severely affect thermal efficiency. Upgrading a property’s Energy Performance Certificate (EPC) by installing an External Wall Insulation (EWI) system, particularly using Kingspan K5, significantly improves energy efficiency. This upgrade not only reduces heat loss through walls but also maintains a consistent internal temperature, increasing thermal comfort. The high R-value of Kingspan K5 contributes to the building’s enhanced energy performance, making the property more energy-efficient and environmentally friendly. This improvement can lead to energy bill savings, increased property value, and compliance with modern energy standards.

In this specific case, the system chosen included 50mm of Kingspan K5, with the U-value to be confirmed, but hopefully meeting retrofit requirements. Building Regulations specify the U-values that retrofits must achieve. U-value quantifies the heat loss through a building component, such as a wall, floor, or roof. It is the reciprocal of the total R-value (U = 1/total R-value), encompassing the resistance offered by the materials and the air films surrounding them. Expressed in watts per square metre Kelvin (W/m²K), a lower U-value indicates a component’s enhanced ability to curtail heat loss, thereby boosting the overall energy efficiency of the building.

In this specific case, the system chosen included 50mm of Kingspan K5, with the U-value to be confirmed, but hopefully meeting retrofit requirements. Building Regulations specify the U-values that retrofits must achieve. U-value quantifies the heat loss through a building component, such as a wall, floor, or roof. It is the reciprocal of the total R-value (U = 1/total R-value), encompassing the resistance offered by the materials and the air films surrounding them. Expressed in watts per square metre Kelvin (W/m²K), a lower U-value indicates a component’s enhanced ability to curtail heat loss, thereby boosting the overall energy efficiency of the building.

Space Saving Properties

Kingspan K5 is renowned for being one of the best-performing insulation boards due to its extremely low thermal conductivity. This characteristic allows it to be considered a space-saving system, as it requires a lower thickness compared to other insulation types. The benefits of having a space-saving system are multi-faceted. For this particular project, the reduced thickness allows the original wooden beams to remain exposed. Additionally, Kingspan K5 is extremely durable and resistant to impact due to its higher compressive strength, providing extra peace of mind for the customer, even though this aspect is less critical in residential areas.

As with any external wall insulation project, the thermal performance is significantly improved, achieving the required U-value for UK Building Regulations. This translates to substantial savings on energy bills for the customers, offering a reasonable payback period. The additional plumbing and window work, alongside the EWI system, significantly enhance the property’s value.

The project incorporated several other elements to maintain its aesthetic appeal. Silicone Render provides a stylish, classical, and weatherproof envelope for the building. The windows were replaced with diamond muntin windows, which lend a classical style that complements the exposed wooden beams.